Production possibilities

Milling

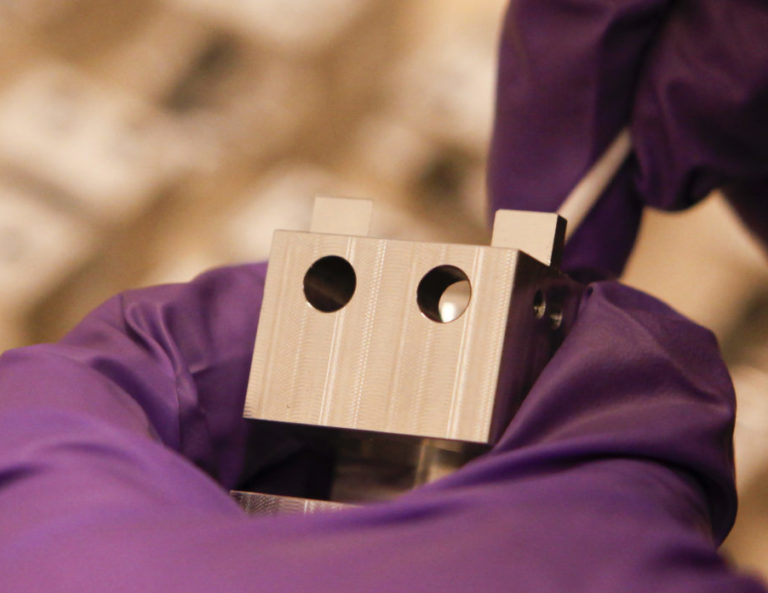

At Kusters & Bosch, prototype parts are almost always made on a 3-axis or 5-axis stand-alone milling machine. Series production of parts is carried out on robotic 5-axis machines. Our aim is to finish the parts on the machine as much as possible.

Milling

At Kusters & Bosch, prototype parts are almost always made on a 3-axis or 5-axis stand-alone milling machine. Series production of parts is carried out on robotic 5-axis machines. Our aim is to finish the parts on the machine as much as possible.

Turning

Serial production of turned parts is carried out on a lathe with a bar feeder. Serial production of parts involving a combination of turning and milling is carried out at Kusters & Bosch on robotic turning machines with powered tools.

Wire EDM

For highly accurate turning and milling parts, Kusters & Bosch uses wire EDM as an additional quality assurance measure. We also use wire EDM for parts that cannot be manufactured in any other way due to their shape or accuracy requirements.

Wire EDM

For highly accurate turning and milling parts, Kusters & Bosch uses wire EDM as an additional quality assurance measure. We also use wire EDM for parts that cannot be manufactured in any other way due to their shape or accuracy requirements.

Assembly

At Kusters & Bosch, you can count on expertise and professionalism in the execution of assembly activities, whereby we carefully monitor the quality of the end product.

Quality assurance

Kusters & Bosch has a conditioned and well-equipped measuring room including 2 3D measuring machines. These machines are sized so that we can fully check all the parts we produce on these machines as well.

The quality department works closely with the craftsmen in the workshop and series production may only be started after clearance by the quality department.

Quality assurance

Kusters & Bosch has a conditioned and well-equipped measuring room including 2 3D measuring machines. These machines are sized so that we can fully check all the parts we produce on these machines as well.

The quality department works closely with the craftsmen in the workshop and series production may only be started after clearance by the quality department.

Machine overview

Kusters & Bosch has machinery at its disposal for tasks such as:

Operations Dimensions (max)

- Wire EDM (400x300x255)

- Turning (625xØ380)

- Milling 3-5 axis (850x700x500)

- Quality assurance (1200x2000x1000)

Operations

- Wire EDM (400x300x255)

- Turning (625xØ380)

- Milling 3-5 axis (850x700x500)

- Quality assurance (1200x2000x1000)

Projects to which Kusters & Bosch contributed

Since 2012, Kusters & Bosch has also been working for science. What once started small is now a real part of our turnover. The scientific institutes we work for are CERN, ESRF, ITER, NOVA and ESO (indirectly).

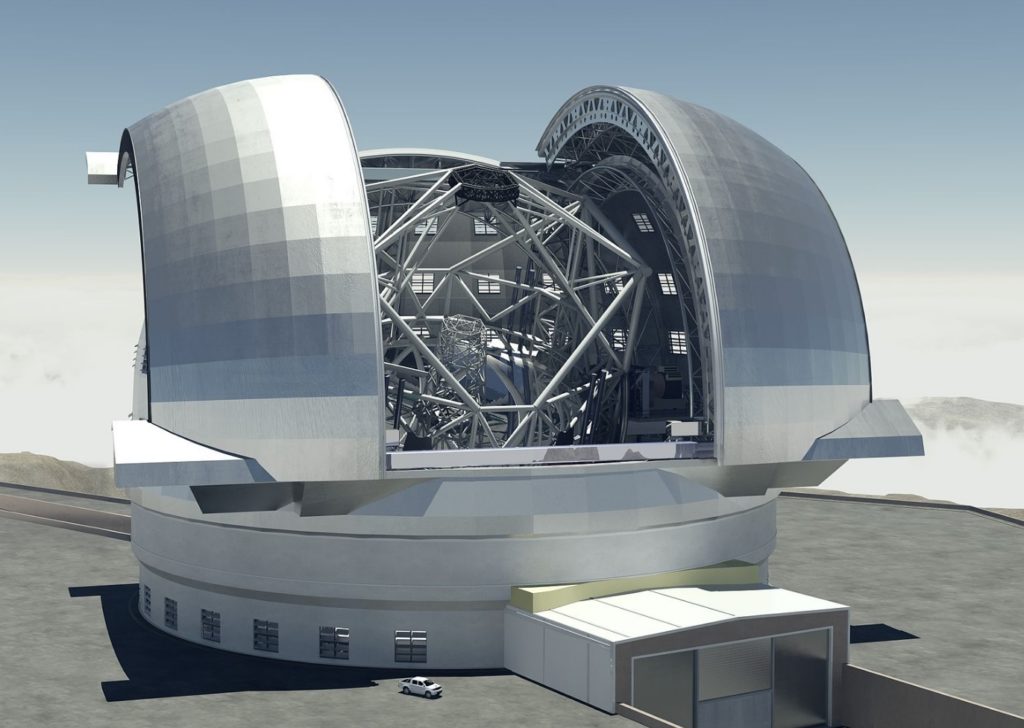

Extremely Large Telescope

Kusters & Bosch has contributed to the largest telescope in the world: the Extremely Large Telescope (ELT). Kusters & Bosch contributed to the components for the telescope's mirror in this project. The ELT will be the largest optical/near-infrared telescope in the world, with a mirror measuring 39 meters in diameter, which is approximately five times larger than the mirrors of the largest telescopes currently in use.

The ELT is expected to be operational in the course of 2027 and will make an important contribution to our understanding of the universe and our place in it.

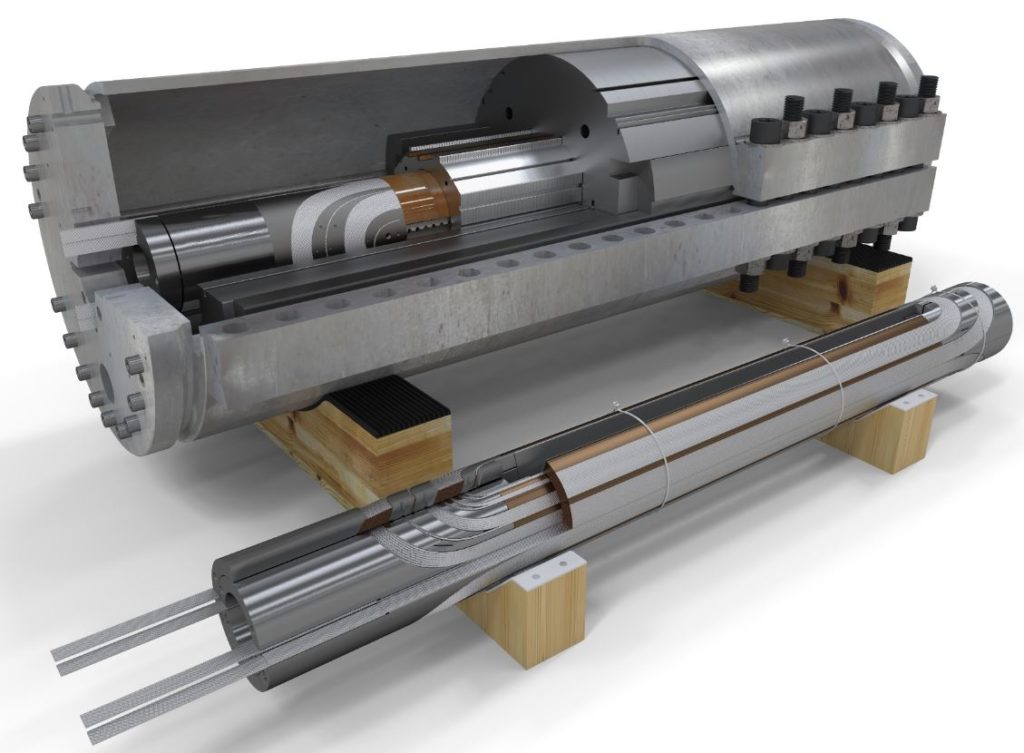

CERN 11-Tesla Magnet

Kusters & Bosch supplied parts for the 11-Tesla Magnet used in CERN's Large Hadron Collider (LHC).

It is one of the most powerful superconducting magnets in the world and is used to accelerate and focus the LHC's particle beams.

The CERN 11-Tesla magnets played an important role in the discovery of the Higgs boson particle, one of the most important discoveries of modern particle physics.